Hybrid Plastic Packaging

A concepts and series of experiments on making composite packaging that appropriately combines the qualities of plastics and bioplastics. It would still use plastic, but much less of it.

Bioplastics vs PlasticsPlastics are very versatile materials. They are waterproof, resistant to degradation, and can take any form. Unfortunately, we use much we have a trash crisis. As long as our societies continue to mass-consume and value the convenience of cheap, single-use products and the increase in plastic packaging, plastics will continue to be produced and used irresponsibly. (1)

Bio-plastics are compostable and can degrade in nature; they are essentially edible (the ‘plastic’. The fact they degrade is partly their disadvantage when it comes to packaging. Lots of bioplastic packaging solutions are still in development, because the aim is to find a formula that allows for feasible packaging that is 100% bioplastic. Until the perfect packaging bio-plastic material is discovered and mass produced, can we not combine the old and new to transition into less plastic-intensive product cycles?

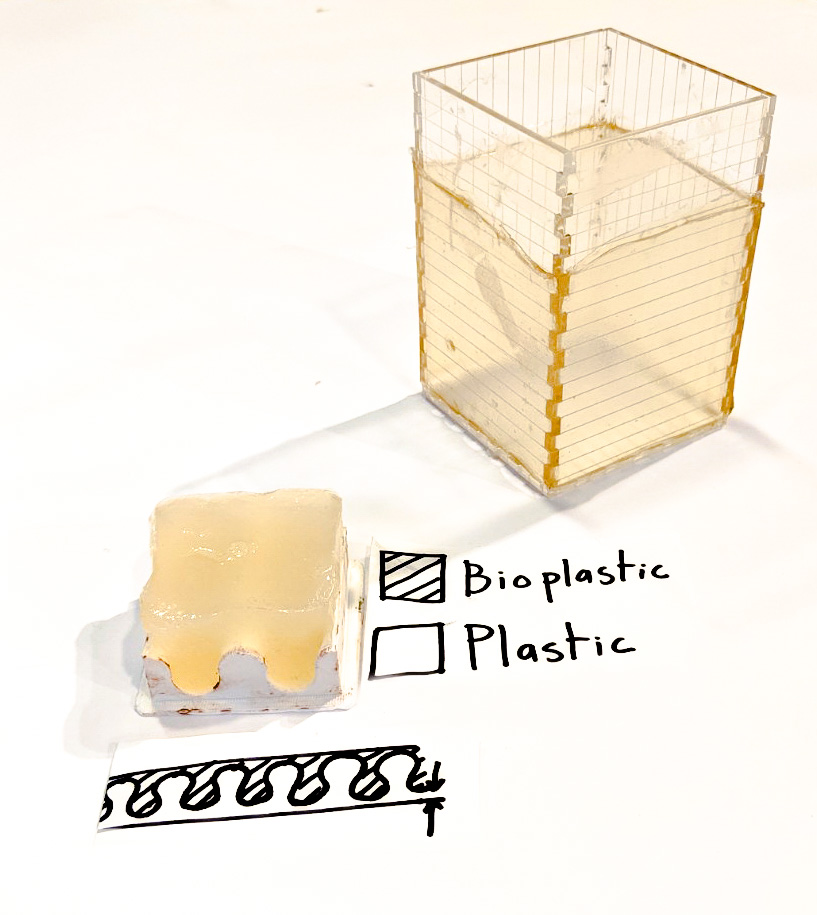

Exterior vs Interior

The bio-plastic exterior provides the short-lived structural support to house the thin, waterproof, plastic interior. Whatever is inside this package (water, juice, food, etc) will not leak.

Composting and Re-useOnce the package is disposed, it can be composted (the outside degrades/eaten by microbes/worms) and the interior could potentially be re-used to make more packaging.

Packaging standardization

If the plastic piece is designed to combine with other identical pieces, it can become a modular building-block of packaging material that circulate in the technosphere, without the plastic having to be melted and reformed.

Packages of all sizes and volumes could be accommodated by puzzling together the plastic interior pieces differently, and different weight/pressure ratings can be achieved by altering the thickness and rigidity of the bio-plastic exterior.

Composting and Re-useOnce the package is disposed, it can be composted (the outside degrades/eaten by microbes/worms) and the interior could potentially be re-used to make more packaging.

Packaging standardization

If the plastic piece is designed to combine with other identical pieces, it can become a modular building-block of packaging material that circulate in the technosphere, without the plastic having to be melted and reformed.

Packages of all sizes and volumes could be accommodated by puzzling together the plastic interior pieces differently, and different weight/pressure ratings can be achieved by altering the thickness and rigidity of the bio-plastic exterior.

Transitionary

Part of this project’s experimental goal is to explore solutions in a space between realistic and ideal, feasible and speculative, natural and technological. For instance to assume that people will not liter is a naive assumption - so part of the plastic pattern’s design (the thin ridges, to make the walls tearable) aims to facilitate the process by which nature can overwhelm, consume, encapsulate, or excrete it - in this case, the use of plastic as a nest-building material (which many birds already do).

This does not address the problems with the harmful additives that leach from plastics into soil and the waterbed, but it solves the issue of the form/size/geometries of plastic packages that end up entangling, choking and strangling wildlife (on land and sea).

Process:

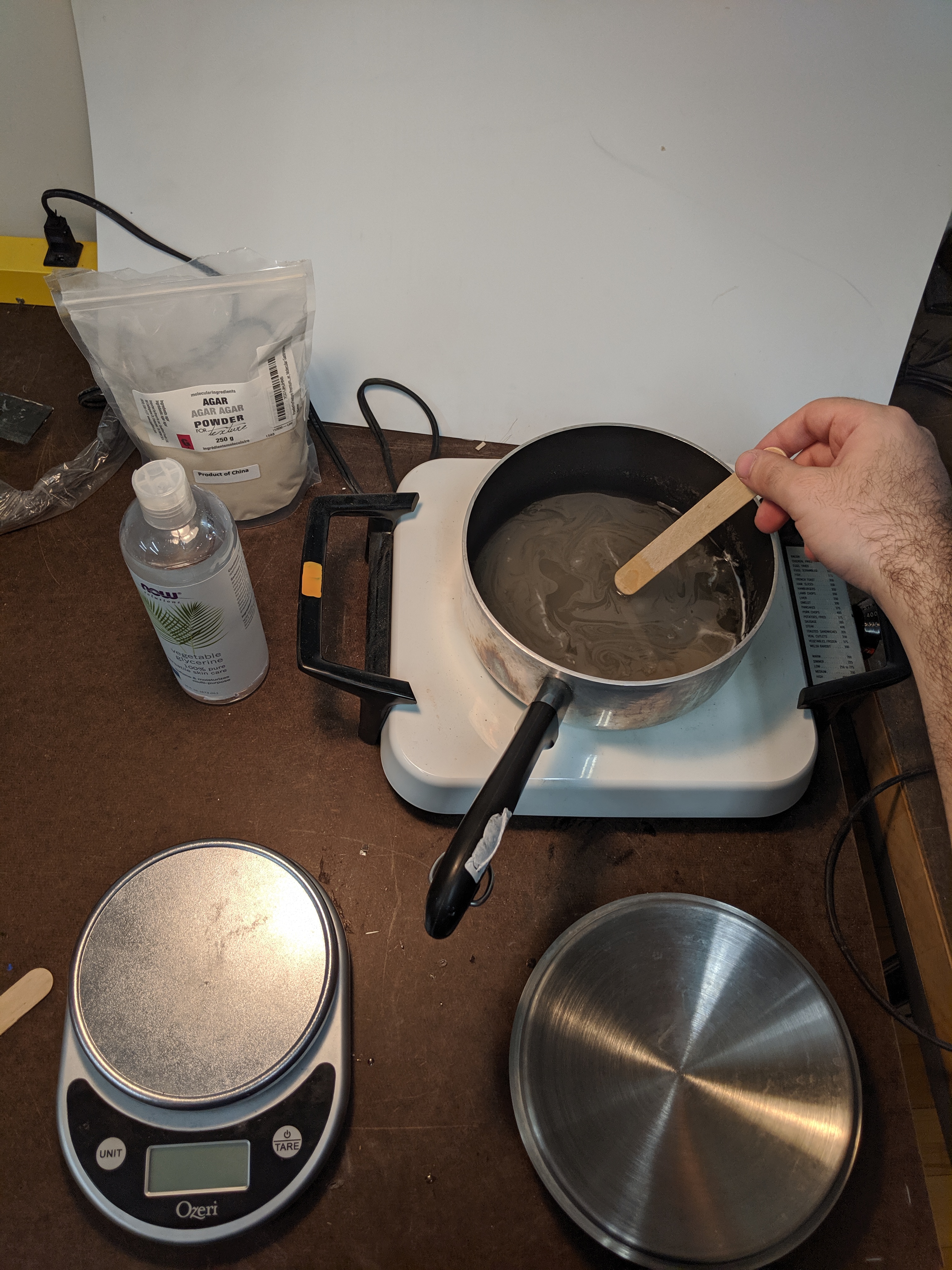

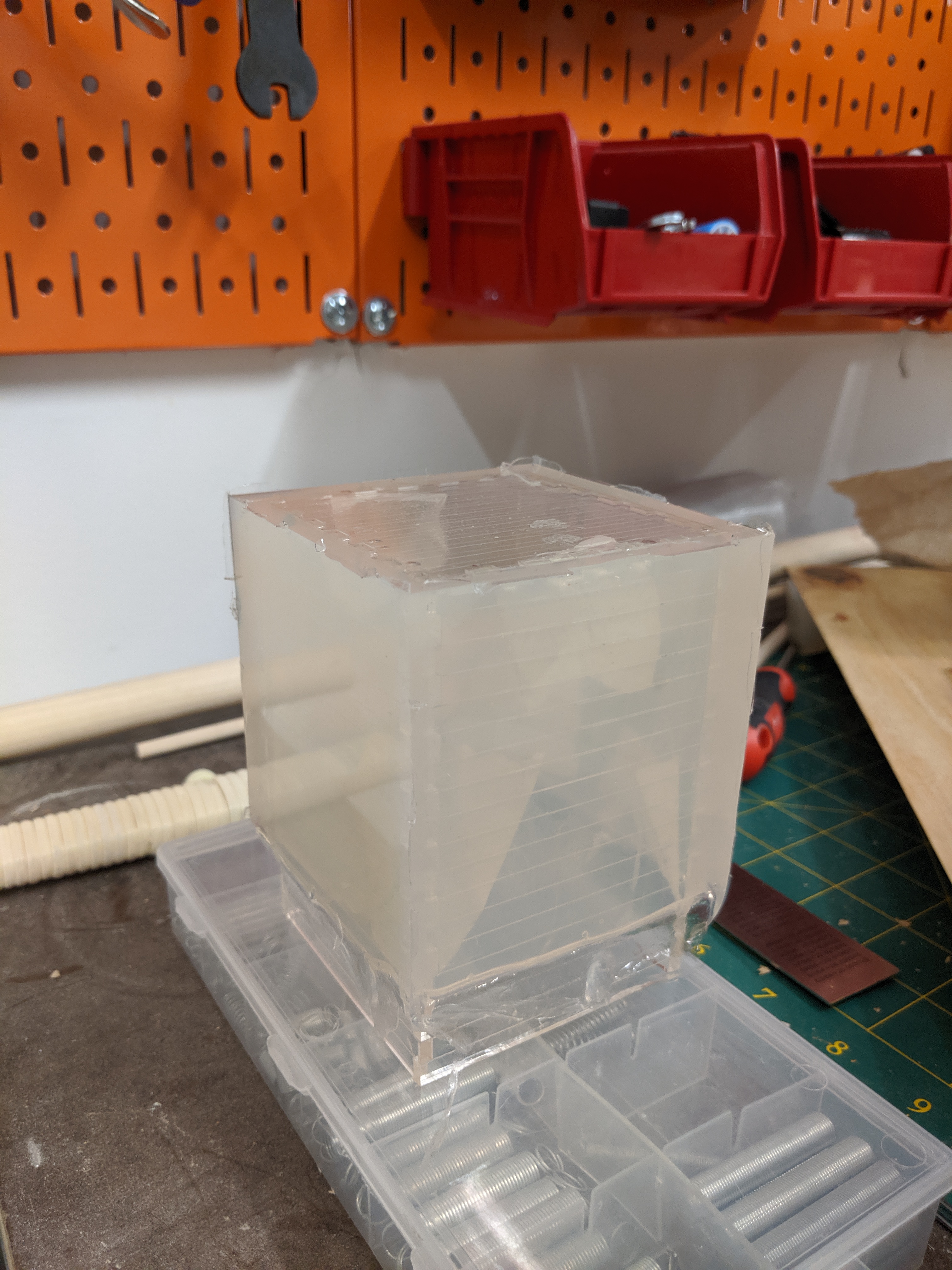

The bioplastic I made is agar agar based (a powder made from algae, jelly-like when cooked). The three ingredients are water, agar agar powder and glycerine. by altering the ratio of agar agar and glycerine I was able to alter the flexibility of the final bioplastic. The biggest challenge is acheiving uniform drying because it involves exposing all the sides of the wet bioplastic to air. if the wet bioplastic is too thick, it takes long to dry and also can crack with the shrinkage.

a piece of bioplastic that was laid flat to dry - the air-exposed side (top) dried first and thus shrunk and bent. Once bent, the bottom side gets exposed to air and begins to shrink - this is what ends up creating wavy edges as the entire piece starts to unevenly dry and warp.

![]()

Potential

If I can continue this experiment, I would investigate different methods of drying (with air flow / temperature / dehymidifying ) as well as altering thickness of plastic interior.I used laser cut acrylic but with more sophisticated manufacturing and tolerances the composition, thickness, and etching pattern of the plastic interior could also be something to explore and perhaps simulate on F.E.A. software to test how they would deal under hydrostatic pressure, shearing (if a bird wants to rip a piece with their beaks) etc. With a longer time-frame, the life-time of the bioplastic can be investigated under different conditions (humidity, temperatures, etc) to determine the transport + shelf-life of the packaging (which may be significantly shorter than the food’s shelf-life).

The bio-plastic shrinkage means that the tension it exerts on the plastic interior (if the interior is thin enough - unlike the acrylic which can take the tension without deforming much) will warp it. Perhaps the interior and exterior are not molded together and are only fitted together post-drying.